The Ultimate Guide to Wire Mesh Cages: Secure Storage and Versatile Solutions

1. Introduction to Wire Mesh Cages

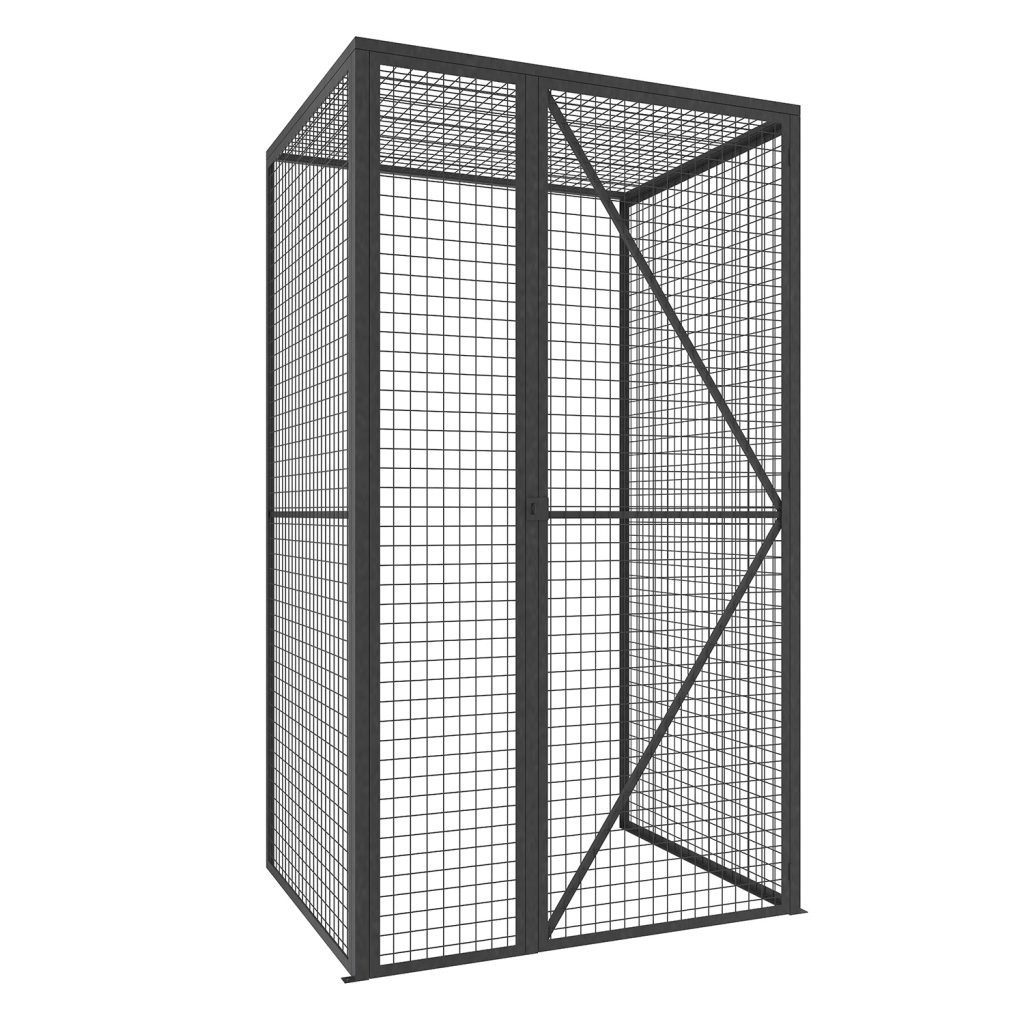

Wire mesh cages are an essential solution for organizations looking to secure their valuable inventory, create safe work areas, or control access to specific zones within their facilities. These cages are made from durable 10-gauge wire, providing both strength and visibility. Unlike solid partitions or fencing, wire mesh cages offer a balance between security and maintaining an open and well-lit environment.

Wire mesh cages are highly customizable,allowing you to create partitions of various sizes and configurations to meet your specific requirements.They can be easily installed and reconfigured as needed, providing flexibility and adaptability to changing needs.Additionally, wire mesh cages are more cost-effective in the long run compared to alternatives like chain link fencing.

In the following sections, we will explore the different types of wire mesh cages available, their advantages over chain link fencing, and the various customization options to create a tailored solution for your organization.

2. Types of Wire Mesh Cages

Wire mesh cages come in two main types:woven wire mesh cages and welded wire mesh cages.Each type has its own characteristics and advantages,making them suitable for different applications.

2.1 Woven Wire Mesh Cages

Woven wire mesh cages are constructed using crimped wire woven into a 1" x 2" mesh pattern. This construction provides excellent strength and security while allowing for visibility and ventilation. Woven wire mesh cages are typically finished in gray acrylic enamel, ensuring long-lasting durability.

2.2 Welded Wire Mesh Cages

Welded wire mesh cages, on the other hand, are created by welding wires at every intersection, forming a 2" x 2" mesh pattern. This welding process enhances the overall strength and rigidity of the cages, making them suitable for high-security situations. Welded wire mesh cages are finished with a gray powder coat, offering resistance against corrosion and wear.

The choice between woven and welded wire mesh cages depends on the specific needs of your application. Woven wire mesh cages are more affordable and provide sufficient security for most situations. On the other hand, if you require enhanced security, welded wire mesh cages are the ideal choice.

3. Comparing Woven and Welded Wire Mesh Cages

While both woven and welded wire mesh cages offer secure storage and separation, they differ in terms of construction and characteristics. Let's take a closer look at the key differences between these two types of wire mesh cages.

Comparison Criteria Woven Wire Mesh Cages Welded Wire Mesh Cages Mesh Pattern 1" x 2" crimped wire 2" x 2" welded wire Finish Gray acrylic enamel Gray powder coat Strength Sufficient for most applications Enhanced strength for high-security situations Visibility Provides good visibility and ventilation Moderate visibility Cost More affordable Slightly more expensive It's important to consider your specific requirements and budget when choosing between woven and welded wire mesh cages. If you need a cost-effective solution that provides sufficient security, woven wire mesh cages are a suitable choice. However, if you require enhanced strength and security, welded wire mesh cages are the recommended option.

4. Customization Options

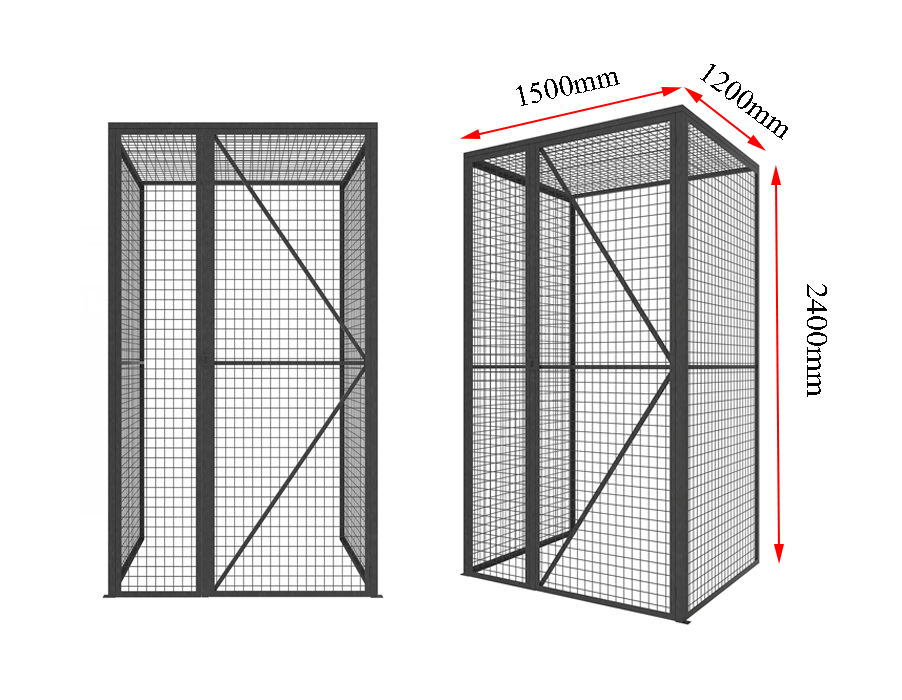

Wire mesh cages offer a wide range of customization options,allowing you to create a tailored solution that fits your specific needs.From size and configuration to wire mesh panels and locking mechanisms,here are some key customization options to consider when designing your wire mesh cage.

4.1 Size and Configuration

Wire mesh cages can be customized to fit any space requirement. Whether you need a small enclosure for a tool crib or a large partition for a stockroom, wire mesh cages can be tailored to your desired dimensions. Additionally, the modular design of wire mesh cages allows for easy expansion or reconfiguration as your needs change.

4.2 Wire Mesh Panels

The selection of wire mesh panels is crucial for the overall strength and security of your wire mesh cage. Choose panels made from durable 10-gauge wire that are compatible with your chosen mesh pattern (1" x 2" for woven wire mesh cages or 2" x 2" for welded wire mesh cages). These panels should be interchangeable, allowing for easy replacement in case of damage or reconfiguration.

4.3 Doors and Access Points

Consider the number and type of doors you require for your wire mesh cage. Whether you need a single swing door or a double sliding door, wire mesh cages can be configured to provide the desired level of access control. Additionally, consider the inclusion of access points such as windows or pass-throughs for the convenient transfer of items.

4.4 Locking Mechanisms

Enhance the security of your wire mesh cage by selecting the appropriate locking mechanism. Various lock types are available, including 5-button access locks, dead-bolt locks, electro-magnetic locks, coded card reader locks, and electric strike locks. Choose the lock type that best suits your security requirements and operational needs.

5. Applications of Wire Mesh Cages

Wire mesh cages find applications in a wide range of industries and environments where secure storage, asset protection, and access control are essential. Here are some common applications of wire mesh cages:

5.1 Stock Rooms

Wire mesh cages are ideal for creating secure stock rooms within warehouses or retail environments. They provide a barrier between valuable inventory and general access, ensuring that only authorized personnel can enter the designated area.

5.2 Tool Cribs

In manufacturing facilities, wire mesh cages can be used as tool cribs to store and organize valuable tools and equipment. By restricting access to authorized personnel, wire mesh cages help prevent loss or theft of tools, ensuring their availability when needed.

5.3 Weapons Storage

Law enforcement agencies, military facilities, and private security companies often require secure storage solutions for weapons and ammunition. Wire mesh cages provide the necessary security while allowing easy visibility and access for inventory management.

5.4 Machine Guarding

Wire mesh cages can be used to create secure enclosures around machinery, providing a physical barrier between operators and potentially hazardous equipment. This helps ensure worker safety and compliance with regulatory requirements.

5.5 High-Value Inventory or Materials

Industries dealing with high-value inventory or materials, such as pharmaceuticals, electronics, or precious metals, can benefit from wire mesh cages. These cages offer enhanced security and visibility, providing peace of mind and reducing the risk of theft or unauthorized access.

5.6 Areas Requiring Access Control

Wire mesh cages can be used to enclose areas that require restricted access, such as server rooms, data centers, or confidential document storage areas. By controlling access to these areas, organizations can protect sensitive information and assets.

Wire mesh cages offer a versatile solution for a wide range of applications. The next section will explore the advantages of wire mesh cages over chain link fencing, highlighting why they are the preferred choice for many organizations.

6. Conclusion

Wire mesh cages offer secure storage, enhanced visibility,and flexibility for a wide range of applications.Whether you need to safeguard valuable inventory,control access to specific areas, or create separate work zones,wire mesh cages provide the ideal solution.With their customizable design,modular construction,and superior security features,wire mesh cages are a cost-effective and versatile choice for organizations of all sizes.By understanding the different types, customization options,and installation considerations,you can create a wire mesh cage that meets your specific requirements and enhances the overall security of your facility.Invest in wire mesh cages to protect your most valuable assets and enjoy the peace of mind that comes with a secure storage solution.