What is the best material for lockers?

How to choose a suitable storage locker? There are many factors that can influence your decision, and materials are one of the important ones. For example, although metal lockers are hard, they are not suitable for use in kitchens, bathrooms, and other wet places. Because the moisture in the air can cause it to quickly rust and rot. Wooden lockers have a beautiful appearance and will not appear abrupt when used in various occasions. But if it is placed in supermarkets, stations, and other crowded places, it may not be able to withstand such high frequency of use and will soon be damaged. Therefore, choosing a suitable material for lockers is very important. This blog will analyze what is the best material for lockers for you.

1. Three different types of locker

1.1.Metal Locker

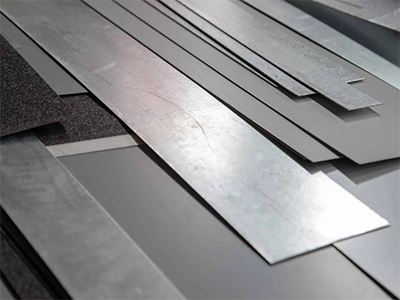

Metal locker is a relatively traditional choice and have always been a standard choice in schools and industrial environments. Because metal lockers have relatively lower production costs. And it is relatively sturdy, able to withstand high-frequency use, suitable for use in places with high pedestrian traffic. If maintained properly, its lifespan can last for over a decade. But its drawbacks are also quite obvious. If the thickness of the board used is relatively thin, it is easy to collide and deform or damage. If the thickness of the board is too thick, the locker will become too bulky. Metal lockers are also affected by weather conditions. It should not be placed outdoors or in environments with high humidity, otherwise it will easily rust. In general, there are several types of materials for metal lockers:

Stainless Steel

- Strong rust and corrosion resistance, suitable for use in humid environments.

- Modern and stylish appearance, easy to clean and maintain.

- Long service life and lower maintenance frequency required.

Galvanized Steel

The surface of galvanized steel has a layer of zinc, which can effectively prevent rust and corrosion. Commonly used in outdoor storage facilities, construction sites, or areas with high humidity.

Aluminum

Aluminum is relatively lightweight and has natural corrosion resistance. For places that require consideration of weight factors, such as cruise ships and RVs, it is an ideal choice.

1.2. Wooden Locker

The use of wooden locker is very common and is generally used in indoor settings. Wooden lockers have significant aesthetic advantages. The natural warm texture, unique texture patterns, and rich colors of wood can create a more attractive and upscale atmosphere. The addition of wooden lockers can elevate the overall quality of the venue. However, the durability of typical wooden lockers cannot compare to that of metal lockers. Wooden lockers are more prone to deformation or damage when bumped. Compared to plastic lockers, wooden lockers are more susceptible to environmental influences. Wooden lockers are generally more suitable for use in dry indoor environments. Next, we will introduce several widely used artificial board materials on the market, which are more affordable in price. The surface can be sprayed, with more appearance options and better moisture resistance than solid wood.

Chipboard

Sawdust and wood chips are pressed into boards and glued together, usually with melamine veneer or veneer on the surface.

Very low cost and easy to process. The surface is flat and easy to apply veneer.

Poor load-bearing capacity and easy to break. Poor moisture resistance, not suitable for use in humid environments.

MDF

Made of wood fiber pressed under high temperature and high pressure. it has a tighter structure, is denser and smoother than particleboard.

The surface is smooth, suitable for painting and veneer processes. The material is uniform and easy to process and carve.

It is easy to expand after absorbing water and is not suitable for environments with high humidity.

Plywood

Made of multiple layers of wood veneer staggered, glued and pressed, the structure has high stability.

Strong load-bearing capacity, not easy to deform, suitable for long-term use.

Good moisture resistance.

Slightly higher cost, rough surface, requires secondary treatment.

1.3. Plastic Locker

The advantages and disadvantages of plastic lockers are relatively obvious. Generally speaking, plastic lockers are cheaper to make. It is a good choice when the budget is limited. Plastic lockers are more waterproof and corrosion-resistant, and can be placed outdoors or in an environment with high humidity without worrying about mold and rot. The surface of plastic lockers is smooth, and dirt is not easy to adhere. Therefore, its daily maintenance is also very simple. Just wipe the surface gently with a wet rag. But the disadvantages of plastic lockers are also obvious. Its durability is worse than that of metal lockers and wooden lockers. Its load-bearing capacity is weak, and it is not suitable to store too heavy items. Otherwise, the locker may be deformed or damaged. Next, several commonly used materials for plastic lockers will be shown to you.

HDPE

- Extremely durable: resistant to dents, scratches, and impacts.

- 100% waterproof: will not rust, corrode, or absorb moisture.

- Chemical-resistant: can withstand acids, alkalis, and cleaning agents.

- Lightweight yet strong – easier to install than metal or wood.

- Limited high-temperature resistance (~120°F/50°C max).

PP

- Excellent chemical resistance

- Lightweight & flexible (less prone to cracking)

- Best For: Laboratory lockers, Industrial storage

ABS

- Good rigidity for lightweight lockers.

- Smooth surface (easy to clean).

- Less impact-resistant than HDPE.

- Can warp under high heat.

- Not ideal for outdoor use (UV degradation).

2. What factors should be considered when chooseing material for lockers?

2.1. Cost

The first thing you need to consider is the cost, which is also one of the biggest factors that will affect your choice. Generally speaking, metal lockers are more expensive than plastic or wooden lockers. But you also need to consider the long-term costs. For example, metal lockers generally have a longer lifespan than wooden lockers and require much less maintenance. A metal locker may last much longer than a cheaper wooden locker. This reduces the need for frequent replacement and is more cost-effective in the long run.

2.2. Securitty

Security is another important factor that influences people's choice of lockers. Whether the items can be kept safe is a basic factor that many users consider. In terms of security, one aspect is that the material itself is strong enough, and the other aspect is that the material can be installed with suitable locks. Metal lockers are often favored because they can be adapted to high-security locks. Compared with some wooden or plastic lockers, metal lockers are made of stronger materials and are difficult for unauthorized people to enter. Some metal alloys are designed to be highly resistant to drilling, cutting or prying, providing better security for valuable or sensitive items. You can choose material for lockers with different security factors according to the preciousness of the items you store.

2.3. Maintenance

The material for lockers should be easy to clean and maintain. Materials with smooth surfaces like metal and plastic are generally easier to wipe down and keep clean than wooden lockers, which may have pores and seams that can easily trap dirt and require more delicate cleaning. Also consider the cost and ease of repair if the locker becomes damaged. Some materials, like metal, may require specialized tools and skills to repair, while others, like plastic, may be more easily repaired using simple adhesives or replacement parts.

2.4. Aesthetics

The material for lockers should match the overall aesthetic of the space where the locker will be installed. For example, metal lockers can be powder coated, painted, etc. to give them a sleek and modern look. Wooden lockers can provide a warm and natural aesthetic that fits more traditional or upscale environments. The choice of color is also an important aspect. Different decorating styles correspond to different colors and create different atmospheres. Being able to choose colors that coordinate with the surrounding environment can enhance the visual appeal of the locker and the aesthetic of the entire space.

3. Recommendations for the best materials in different environments

🏫 Schools:Metal or HDPE

- Metal lockers are durable and suitable for frequent use

- HDPE is moisture-resistant, scratch-resistant, and quieter when opening and closing

🏋️♀️ Gyms: HDPE

- Water-resistant and ideal for humid, wet environments

- Rust-proof, easy to clean, and impact-resistant

🏨 Hotels: HDPE or ABS

- Both offer a clean, modern look and are moisture-resistant

- Designed for high traffic and hygienic environments

🏠 Homes: Plastic or Wood

- Cost-effective with a variety of styles

- Less frequent use requires lower durability

🏢 Commercial Spaces: Metal or Wood

- Metal lockers offer structural uniformity and easy mass installation

- Laminated wood adds a premium, stylish appearance

In conclusion, the "best" material for lockers depends on your specific needs and the occasion in which they will be used. If you place more emphasis on security and durability, metal lockers are your first choice. If you want an environmentally friendly and aesthetically pleasing choice, wooden lockers combine functionality with warmth and elegance. For those seeking affordability and versatility, plastic lockers offer a lightweight, affordable, moisture-resistant, and easy-to-clean solution.

Join the Conversation: Locker Materials Talk