The Ultimate Guide to Warehouse Cage Fencing: Enhancing Security and Organization

Benefits of Warehouse Cage Fencing

Enhanced Security and Theft Prevention

One of the primary reasons businesses invest in warehouse cage fencing is to enhance security and prevent theft. By creating physical barriers around valuable inventory and equipment, warehouse cage fencing acts as a deterrent for unauthorized access. The sturdy construction and high-quality materials of these cages make it extremely difficult for intruders to breach, providing peace of mind for warehouse owners and managers.

Improved Organization and Inventory Management

Warehouse cage fencing also offers significant benefits in terms of organization and inventory management. By segregating different areas within the warehouse, such as storage spaces and tool cribs, cage fencing helps maintain order and streamline operations. It allows for efficient space utilization, ensuring that items are stored in designated areas, reducing the chances of misplacement or loss.

Compliance with Safety Regulations

In addition to security and organization, warehouse cage fencing helps businesses comply with safety regulations. By installing cages around hazardous materials or restricted areas, warehouse owners can ensure that only authorized personnel have access to these spaces. This not only prevents accidents and injuries but also avoids potential legal issues and penalties.

Types of Warehouse Cage Fencing

Warehouse cage fencing comes in various types, each designed to cater to specific security and storage needs. Let's explore some of the most commonly used types of warehouse cage fencing:

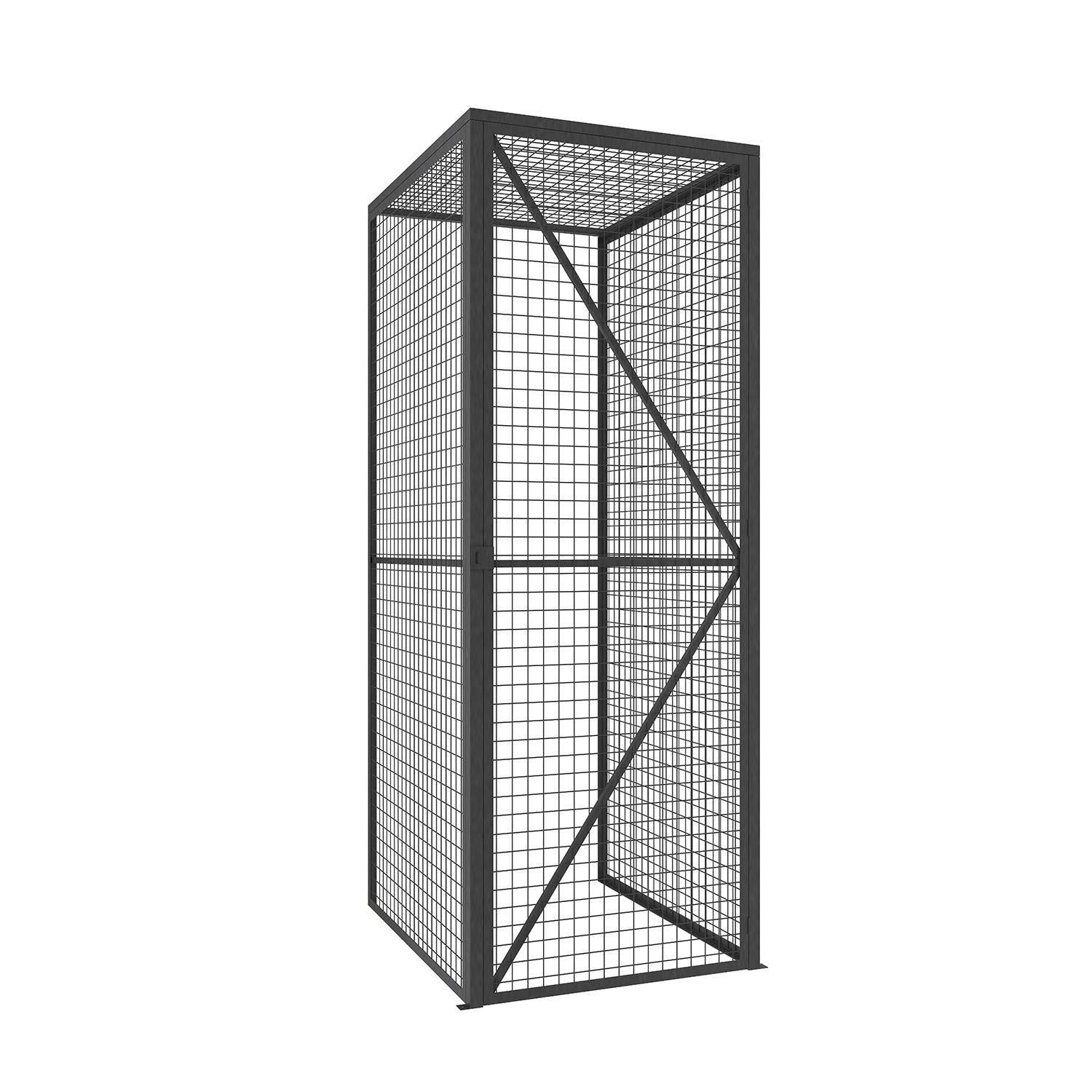

1. Wire Mesh Security Cages

Wire mesh security cages are the most popular choice for warehouse owners due to their versatility and durability. Made from high-strength steel wires, these cages provide a secure enclosure while allowing visibility and airflow. They are ideal for securing valuable inventory, tools, and equipment, and can be customized to fit any space or requirement.

2. Tool Crib Storage Cages

Tool crib storage cages are specifically designed to secure valuable tools and equipment within a warehouse or construction site. These cages provide a designated area for storing tools, reducing the risk of loss or theft. Tool crib storage cages are available in various sizes and configurations to accommodate different tool types and quantities.

3. Driver Cages

Driver cages are commonly used in warehouses and distribution centers to create a secure space for truck drivers to check-in or pick up shipments. These cages act as a buffer zone between the loading dock and the rest of the facility,ensuring that only authorized individuals can access sensitive areas.

4. Holding Cells

In certain warehouse environments, holding cells may be required for temporary detainment of individuals. Holding cell cages are constructed with strong materials and robust locking mechanisms to ensure the safety and security of both detainees and warehouse personnel.

Installation Process

Installing warehouse cage fencing requires careful planning and execution to ensure optimal security and functionality. Here's a step-by-step overview of the installation process:

1. Needs Assessment and Design

The first step in the installation process is to assess your warehouse's specific needs and design the cage fencing layout accordingly. Consider factors such as the size of the area to be enclosed, the type of items to be stored, and any specific security requirements.

2. Site Preparation

Before installing the cage fencing, ensure that the site is properly prepared. This may involve clearing the area, leveling the ground, and making any necessary modifications to the existing infrastructure.

3. Framework Assembly

Next, assemble the framework of the cage fencing according to the design specifications. This typically involves attaching the posts and connecting them with horizontal and vertical wires or panels.

4. Mesh Panel Installation

Once the framework is in place, install the wire mesh panels to create the physical enclosure. Ensure that the panels are securely attached to the framework, providing a seamless and robust barrier.

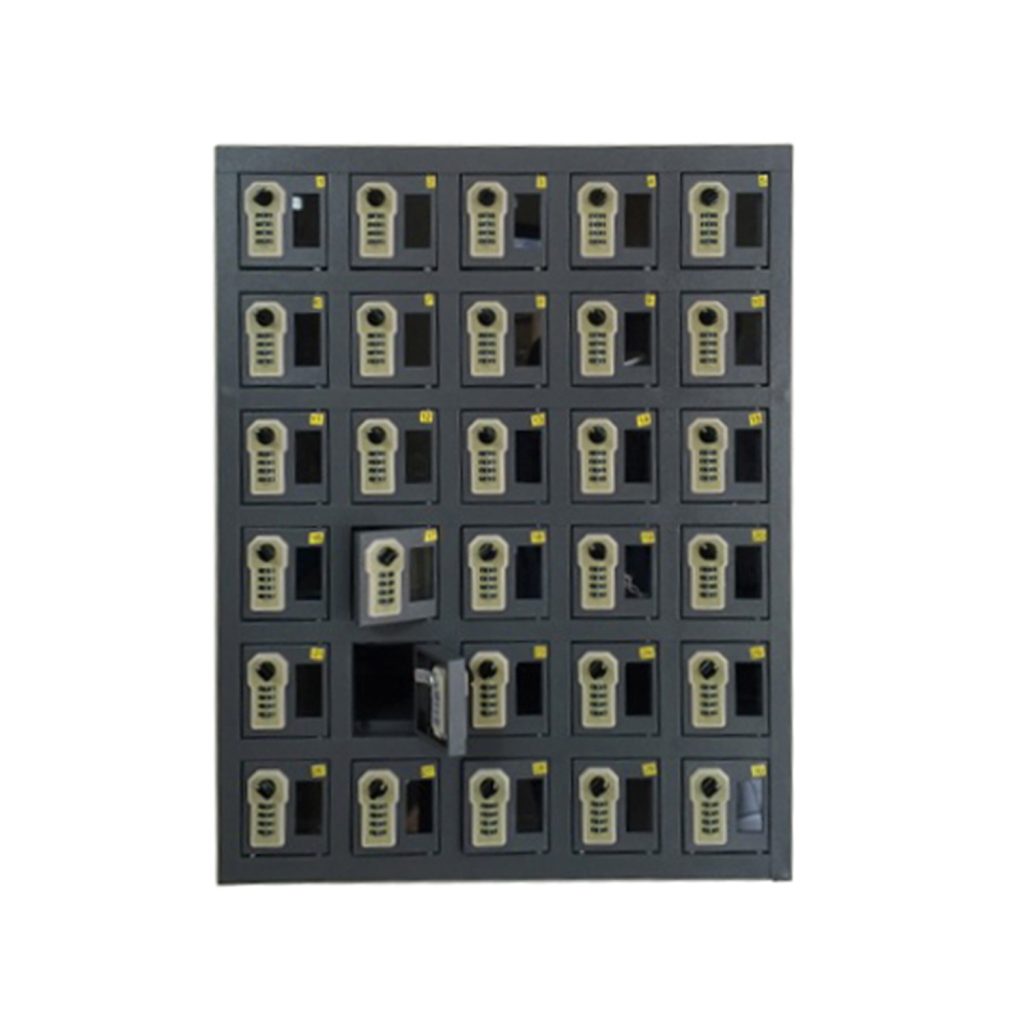

5. Locking Mechanism Installation

Install the locking mechanisms on the cage fencing to ensure controlled access. Depending on the level of security required, options range from standard padlocks to advanced electronic locks.

6. Quality Assurance and Testing

Before finalizing the installation, conduct a thorough quality assurance check and testing of the cage fencing system. This includes inspecting all connections, verifying the functionality of security features, and ensuring that the fencing meets all safety and regulatory standards.

Conclusion

Warehouse cage fencing provides a comprehensive solution for enhancing security and organization in warehouses and distribution centers. By investing in high-quality cage fencing, businesses can protect valuable inventory, streamline operations, and ensure compliance with safety regulations. Whether you need wire mesh security cages, server security cages, or tool crib storage cages, there are various types of cage fencing available to cater to your specific requirements. By following the installation process and choosing reputable brands, you can create a secure and efficient warehouse environment. Don't compromise on the safety of your assets - explore the world of warehouse cage fencing and take your warehouse security to the next level.